|

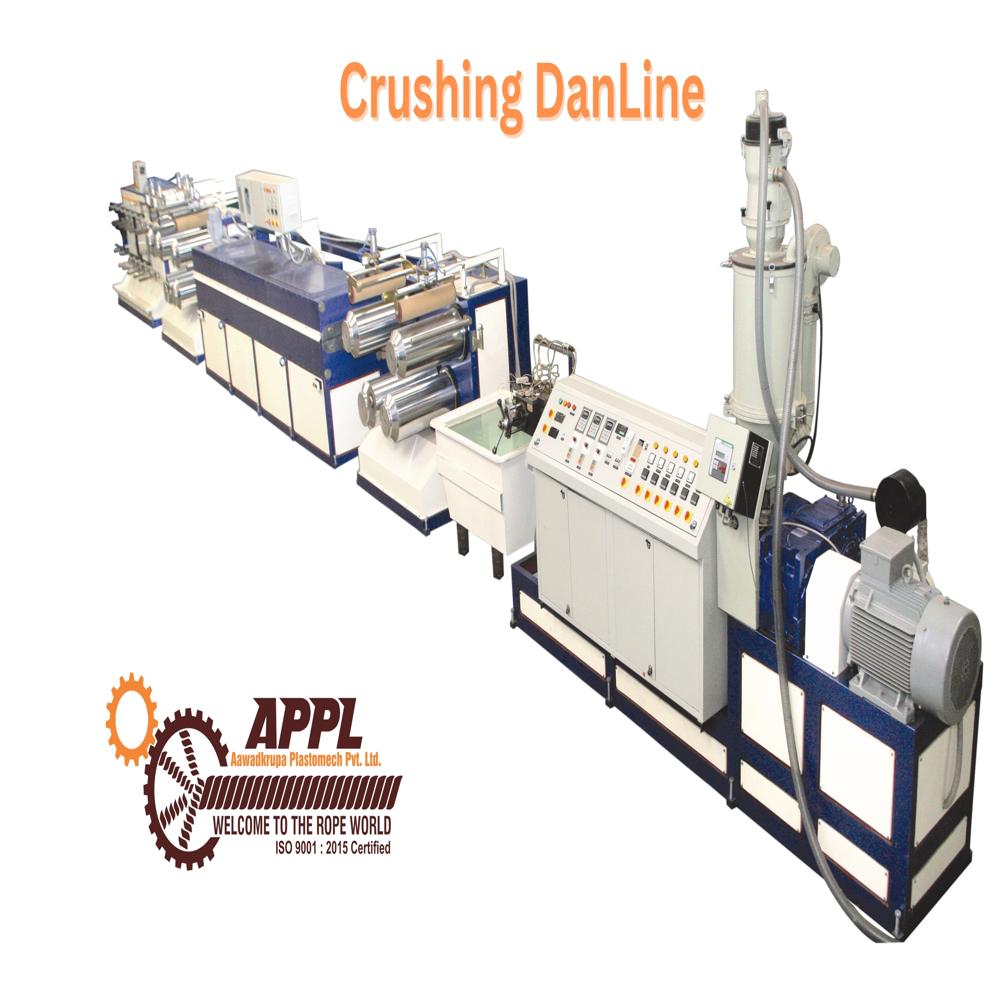

90mm Crushing Danline Extrusion Plant

90mm Crushing Danline Extrusion Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Pipavav Port

- Payment Terms

- Cash Advance (CA), Cheque, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 3 Months

- Sample Available

- No

- Packaging Details

- Shrink & Babble Packing

- Main Export Market(s)

- South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Australia, Central America, North America

- Main Domestic Market

- All India

- Certifications

- ISO 9001 & CE Certified

About 90mm Crushing Danline Extrusion Plant

MONO DAN LINE / CRSHING DAN LINE

Key Features

Extra Strength & Shining To Yarn.

Longer Life of Screw & Barrel.

PP & HDPE can Be Process

More Power Saving in Heater due to Self-Calibration Technology

Especially Design Barrel Heater's Cover With Double insulated Glass Wool for Power Saving.

User Friendly Touch Screen Display With Separate Desk.

All Parameters And Reading Will Be Shown On Display.

Recipe Based Operating System For Easy Machine Operating.

Timer Based Auto-Start Up and Shut Down Heating System.

Reverse Heating Interlocking System to Avoid Damage Of Machine

Emergency Full Length Foot Switches Parallel To The Godded Length For Both Godded.

Safety Guard on Rubber Pressing Roller to Avoid Any Damage.

Energy Calculation For Production And Power Cost On Display Screen.

Speed Control System For More Stretching Accuracy.

Inter Locking Features To Avoid The Damages Of Machine Components.

Shift Wise, Daily, Weekly And Monthly Production Reports.

Machine Lubrication Warning Visible On Display.

AC Drive Fault Alarm Indication On Display.

Wi-Fi or LAN Connectivity.

Remote Monitoring / Remote Maintenance.

Inbuilt Guide For Extruder Settings & Amp;

Inbuilt User Manual In HMI.

Specially Designed Screw & Barrel for Effective Force Mixing and Melting.

Double Insulated With Centrally Calibrated Hot Air Oven With Double Blower.

Grinded Gear to Gear Drive for Smooth Operation on filament in Godded

Extra Features

Pneumatically Operated Transparent Safety Fence Guard For Godded Rollers

Decreased Line Speed During Godded Safety Guard Operation For Easy Yarn Tackling.

Oil Smoothing System for more shining and greasy filament

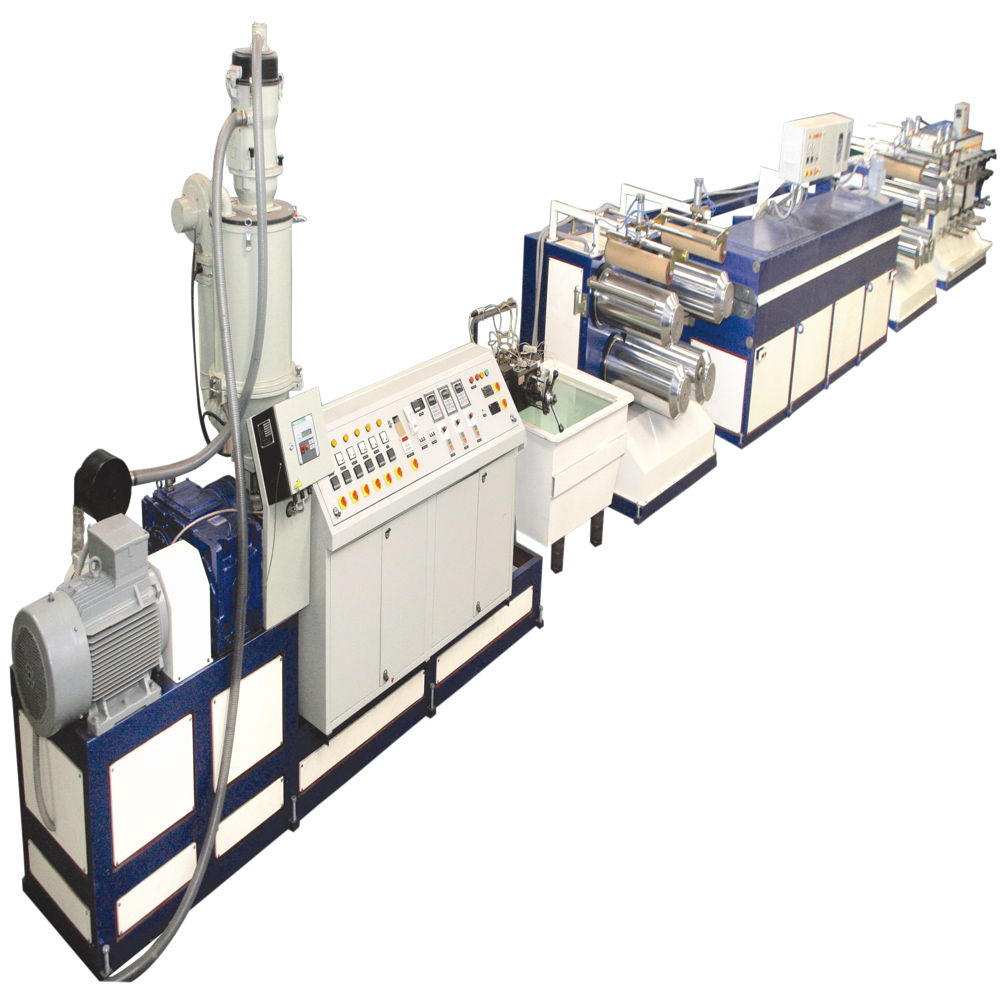

Advanced Heating Zones for Optimal Extrusion

Equipped with five distinct heating zones, the Crushing Danline Extrusion Plant ensures uniform temperature control throughout the barrel. The use of ceramic or aluminum cast heaters maximizes heating efficiency, resulting in superior processing quality for HDPE and PP ropes. This advanced setup reduces thermal fluctuations and contributes to consistent rope diameter and strength.

Automated Production and Precision Control

With a PLC-based control system and inverter-driven AC motor, the plant delivers automated functionality for reliable operation. Users can fine-tune extrusion parameters in real-time, ensuring accuracy and ease of use. The system's automation enhances productivity, minimizes human error, and supports continuous high-capacity output.

Robust Construction and Versatile Applications

Built for industrial environments, the 90mm Crushing Danline Extrusion Plant features a helical gearbox with inbuilt thrust bearing, EN41B nitrided screw, and a stainless steel magnetized feeding hopper. Designed to process HDPE and PP materials, it efficiently produces danline ropes suitable for agricultural, marine, and general industrial applications.

FAQ's of 90mm Crushing Danline Extrusion Plant:

Q: How does the plant ensure consistent rope quality during the extrusion process?

A: The 90mm Crushing Danline Extrusion Plant maintains consistent rope quality through precise PLC control, five heating zones, and a robust cooling system. These features stabilize temperatures and processing conditions, optimizing the properties of HDPE and PP ropes produced.Q: What materials can be processed in this extrusion plant?

A: This extrusion plant is designed to process both HDPE and PP materials, making it ideal for producing high-quality danline ropes suitable for various industrial needs.Q: When is the optimal time to maintain or service the extrusion plant?

A: It is recommended to perform scheduled maintenance every few months or after substantial production cycles. Regular checks of heaters, screw, gearbox, and cooling systems help ensure long-term operational reliability.Q: Where is the Crushing Danline Extrusion Plant manufactured and exported from?

A: The plant is manufactured, supplied, and exported from India, meeting international standards for quality and efficiency in industrial rope manufacturing applications.Q: What is the process flow for making ropes with this extrusion plant?

A: The process involves feeding HDPE/PP granules into the stainless steel hopper, extrusion through the nitrided screw barrel with controlled heating, forming the rope at adjustable diameters, cooling via water or blower systems, and winding at targeted line speed.Q: What are the main benefits of using an inverter-driven AC motor and PLC control?

A: An inverter-driven AC motor, coupled with PLC control, provides precise speed regulation, improved energy efficiency, and automation. This combination helps achieve high output rates with minimal downtime and consistent product specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crushing Danline Extrusion Plant Category

|

AAWADKRUPA PLASTOMECH PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |