|

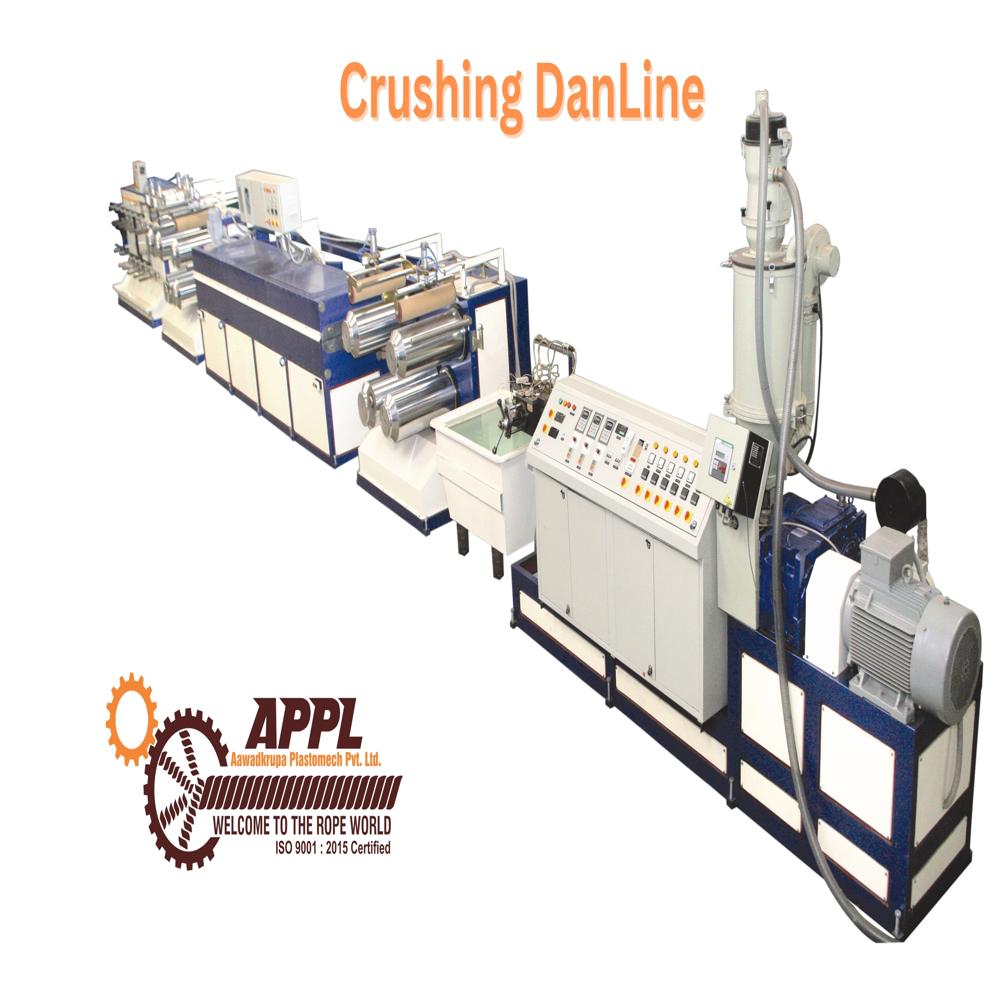

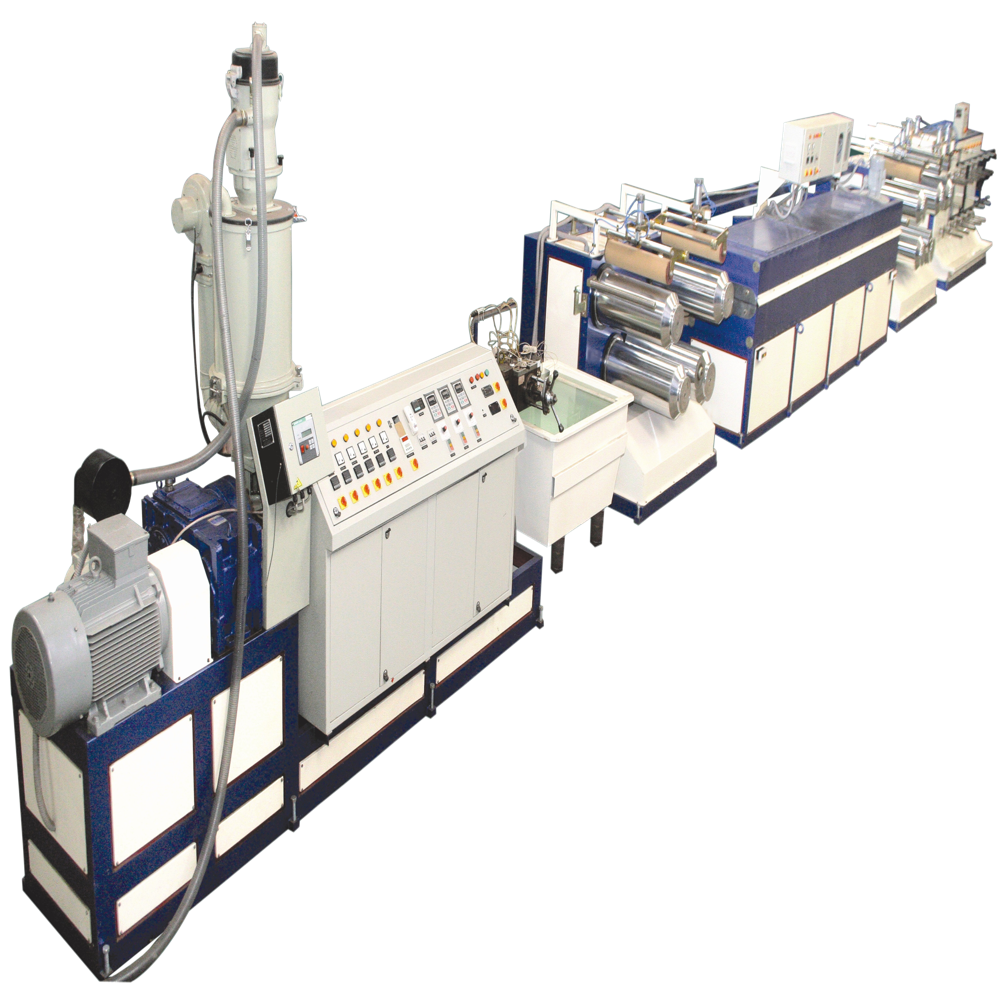

75mm Crushing Danline Extrusion Plant

75mm Crushing Danline Extrusion Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Pipavav Port

- Payment Terms

- Cash Advance (CA), Cheque, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 3 Months

- Sample Available

- No

- Packaging Details

- Shrink & Babble Packing

- Main Export Market(s)

- Africa, Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East

- Main Domestic Market

- All India

- Certifications

- ISO 9001 & CE Certified

About 75mm Crushing Danline Extrusion Plant

Aawadkrupa Plastomech Pvt. Ltd. is a leading manufacturer and exporter of plastic extrusion plants and rope-making machines in India. Established in 1996, the company is powered by a team of young, skilled, and dedicated engineers focused on innovation and quality. In 2000, we started manufacturing monofilament extrusion plants and gradually expanded our expertise to deliver complete turnkey solutions for plastic rope production. Our product range includes advanced ring twister machines, high-speed rope-making machines, and other related equipment designed for durability, efficiency, and long-term performance. With years of industry experience and a strong customer-focused approach, Aawadkrupa Plastomech has earned a reputation for delivering reliable and customized machinery solutions across domestic and international markets. We continuously invest in research and development to keep up with modern production needs and technological advancements. Whether youre starting a new project or upgrading an existing setup, we are your trusted partner in rope manufacturing solutions.MONO DAN LINE / CRSHING DAN LINE

Key Features

Extra Strength & Shining To Yarn.

Longer Life of Screw & Barrel.

PP & HDPE can Be Process

More Power Saving in Heater due to Self-Calibration Technology

Especially Design Barrel Heater's Cover With Double insulated Glass Wool for Power Saving.

User Friendly Touch Screen Display With Separate Desk.

All Parameters And Reading Will Be Shown On Display.

Recipe Based Operating System For Easy Machine Operating.

Timer Based Auto-Start Up and Shut Down Heating System.

Reverse Heating Interlocking System to Avoid Damage Of Machine

Emergency Full Length Foot Switches Parallel To The Godded Length For Both Godded.

Safety Guard on Rubber Pressing Roller to Avoid Any Damage.

Energy Calculation For Production And Power Cost On Display Screen.

Speed Control System For More Stretching Accuracy.

Inter Locking Features To Avoid The Damages Of Machine Components.

Shift Wise, Daily, Weekly And Monthly Production Reports.

Machine Lubrication Warning Visible On Display.

AC Drive Fault Alarm Indication On Display.

Wi-Fi or LAN Connectivity.

Remote Monitoring / Remote Maintenance.

Inbuilt Guide For Extruder Settings & Amp;

Inbuilt User Manual In HMI.

Specially Designed Screw & Barrel for Effective Force Mixing and Melting.

Double Insulated With Centrally Calibrated Hot Air Oven With Double Blower.

Grinded Gear to Gear Drive for Smooth Operation on filament in Godded

Extra Features

Pneumatically Operated Transparent Safety Fence Guard For Godded Rollers

Decreased Line Speed During Godded Safety Guard Operation For Easy Yarn Tackling.

Oil Smoothing System for more shining and greasy filament

Efficient Rope and Twine Manufacturing

The 75mm Crushing Danline Extrusion Plant enables streamlined production of ropes and twines with exceptional strength and tenacity. Its high-speed operation, ability to handle HDPE, PP, and Danline materials, and automatic controls contribute to continuous, quality-focused manufacturing ideal for industrial and commercial applications.

Advanced Process Control

Equipped with an automatic control panel, temperature controllers, and four dedicated heating zones, this extrusion plant ensures optimal process control and uniform product properties. The integration of air and water-cooling further enhances operational stability and material integrity.

Durable and Customizable Engineering

The system features a single screw extruder with a 75mm diameter and sturdy, precision-engineered gearbox. The main motor can be supplied from leading brands as per client requirements, ensuring compatibility and reliable operation tailored to different production needs.

FAQ's of 75mm Crushing Danline Extrusion Plant:

Q: How does the integrated crushing and pelletizing unit benefit the production process?

A: The integrated crushing and pelletizing unit increases operational efficiency by recycling scrap material and converting it directly into usable pellets, thus minimizing waste and reducing the need for additional processing equipment.Q: What materials can be used with the 75mm Crushing Danline Extrusion Plant?

A: The plant is designed for processing HDPE, PP, and Danline materials, allowing manufacturers to produce a diverse range of high-strength ropes and twines.Q: Where is this extrusion plant commonly used?

A: This extrusion plant is predominantly used in rope and twine manufacturing industries, serving applications that require strong, durable, and high-tenacity products, such as fishing, agriculture, packaging, and industrial sectors.Q: What process control features does the plant offer?

A: It includes an automatic control panel equipped with temperature controllers and control switches, as well as four heating zones for precise temperature management throughout the extrusion process.Q: When should you opt for a plant with a single screw extruder design?

A: A single screw extruder is ideal when uniform material melting and consistent extrusion rates are needed, making it well-suited for rope and twine production using HDPE, PP, or Danline.Q: What are the key operational benefits of the air and water cooling system?

A: The combined air and water-cooling system ensures rapid and efficient cooling of the die and barrel, which enhances the mechanical properties of the final product and maintains consistent production quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Crushing Danline Extrusion Plant Category

|

AAWADKRUPA PLASTOMECH PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |